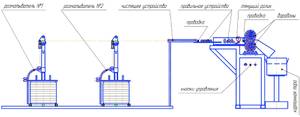

Steel Anchor Fiber Production Line

Production line

steel fiber anchor type 1/50, EN 14889-1: 2006

Specifications:

Wire diameter .............................. 1 mm;

The tensile strength of the wire ....... ...... 1300 N / mm2;

Fiber Length ………………………… ..50 mm;

Productivity ………………… .120 kg / hour (in 2 threads, with a coefficient of equipment utilization - 0.9);

Drive power …………………… 3 kW;

Dimensions: length ................................... 5000 mm;

width ................................ 900 mm;

height ................................. 1400 mm.

7. Mass ............................................... ........ 380 kg.

The machine is equipped with cleaning and correct devices, and also has the ability to smoothly adjust the speed using the Lenze frequency converter, which allows you to adjust the production speed, depending on the quality of the wire. The cutting tool is made of high-strength tool steel, which makes it possible to produce about 10 tons of fiber without re-grinding. Unwinding devices are designed specifically for the use of coils of wire weighing from 50 to 100 kg and allow you to take turns smoothly without jerking and loops, allow you to work with Z2 coils 500-1000 kg. When filling containers, a special device of oriented laying is used, which allows to increase the bulk density of the fiber, therefore, reduce the dimensions of the container and, most importantly, avoid the effect of the formation of "hedgehogs" when mixing fiber-reinforced concrete. The high quality of our equipment allowed us to certify the products of our company - steel anchor fiber 1/50 DMW - in accordance with the requirements of EN 14889-1: 2006 and export the products to EU countries. According to customer requirements, the line can operate in four threads (when supplying wire on a Z2 coil).